Brief Introduction of 7 Segment LED Display /Dot Matrix LED Display Production Process

7 Segment LED Display, LED Display, 7 Segment display, Numeric LED Display;seven segment; LED Display Module, Customized LED Display,Oven timer led display, temperature/humidity led display,refrigerator led display,led display manufacturer ,Dot matrix LED Display.

Substrate Preparation:

Clean the PCB substrate using ultrasonic methods to remove contaminants, followed by drying.

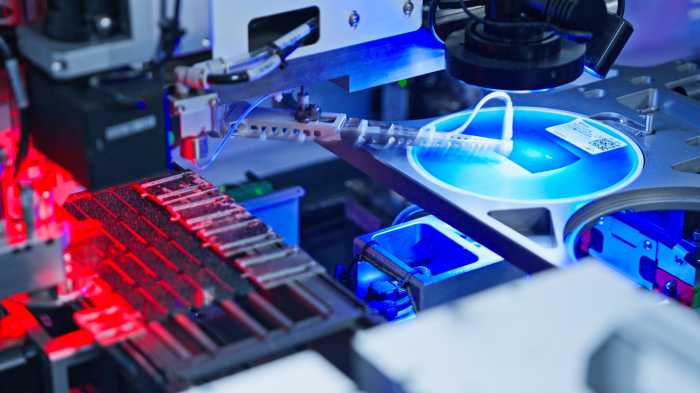

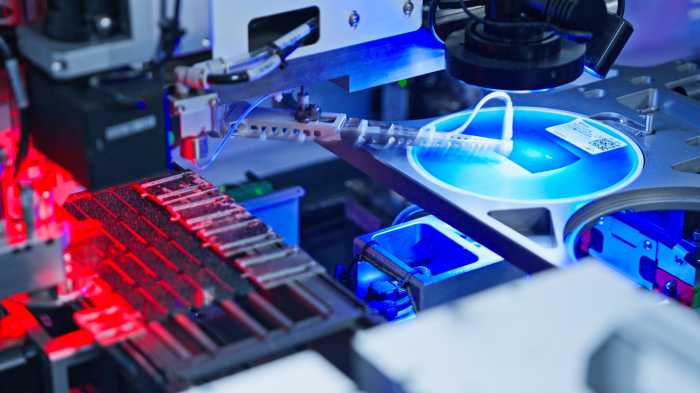

Die Bonding:

Dispense silver paste or insulating glue onto predefined pads of the PCB. Pre-expanded LED chips are precisely mounted onto the pads using a die bonder under microscopic alignment. The assembly is then sintered to cure the adhesive.

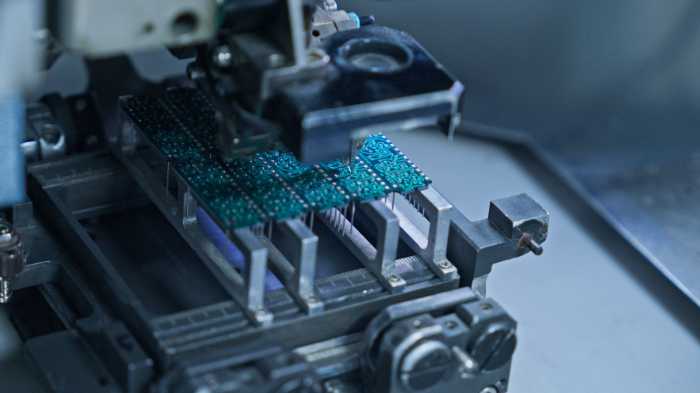

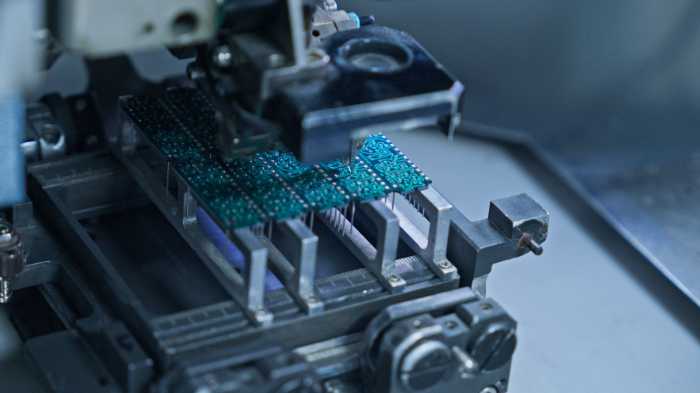

Wire Bonding:

Connect electrode terminals of each LED chip to the PCB's circuit traces using gold/aluminum wires through a wire bonding machine. This establishes electrical pathways for segment control.

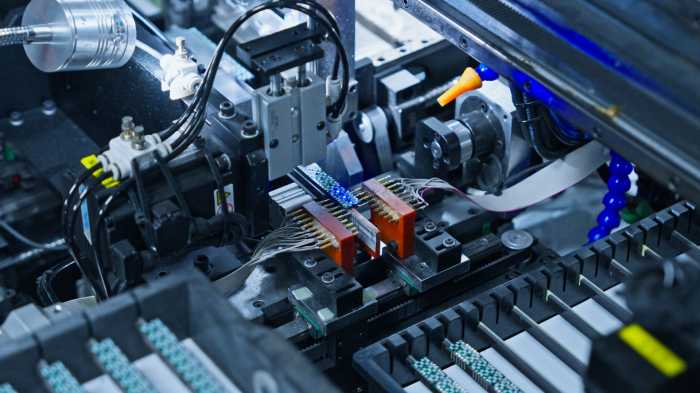

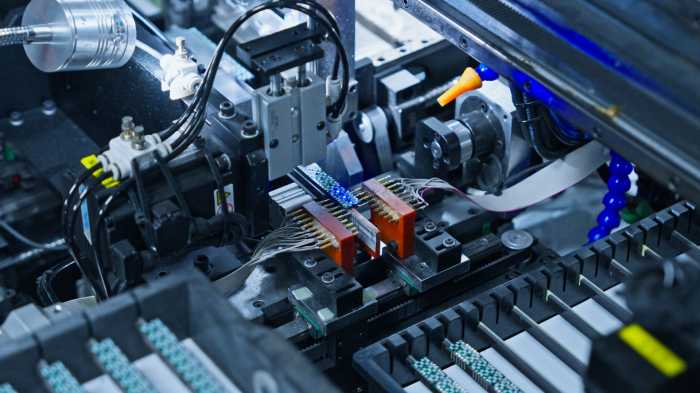

Semi-finished Products Testing : Verity if the leds and wire are well bonded .

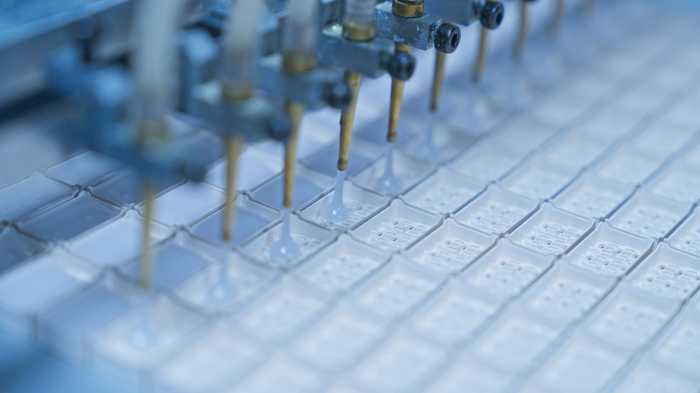

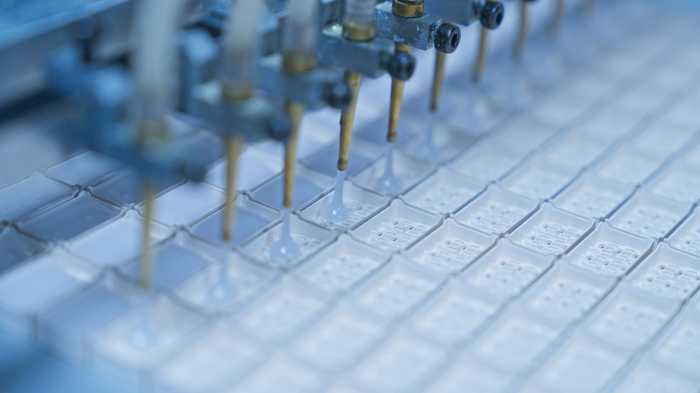

Epoxy Encapsulation:

Apply epoxy resin to encapsulate the bonded chips and wires. The epoxy protects components from environmental factors (e.g., moisture, dust), enhances light diffusion, and may integrate phosphor for color adjustment. Precise control over epoxy shape and volume is critical for luminance uniformity.

Finished Products Testing :

Verify photoelectric parameters (e.g., brightness, color consistency) and segment functionality.

Finished products appearance inspection:

Verify if there is short pins, less pins, pins filled with epoxy,dirty on segments, lastic ref broken,part number well printedand correct, sticker/film sticked properly , etc.

Packaging:

Packaging:Final LED Display are packaged according to specifications.