How to Choose Between Pin Through Hole (DIP) and Surface Mount (SMD) 7-Segment LED Displays

Selecting the right 7-segment LED display for your electronics project involves weighing factors like assembly methods, environmental demands, design constraints, and performance needs. Here is a structured comparison to guide your decision .

1. Physical Design & Assembly

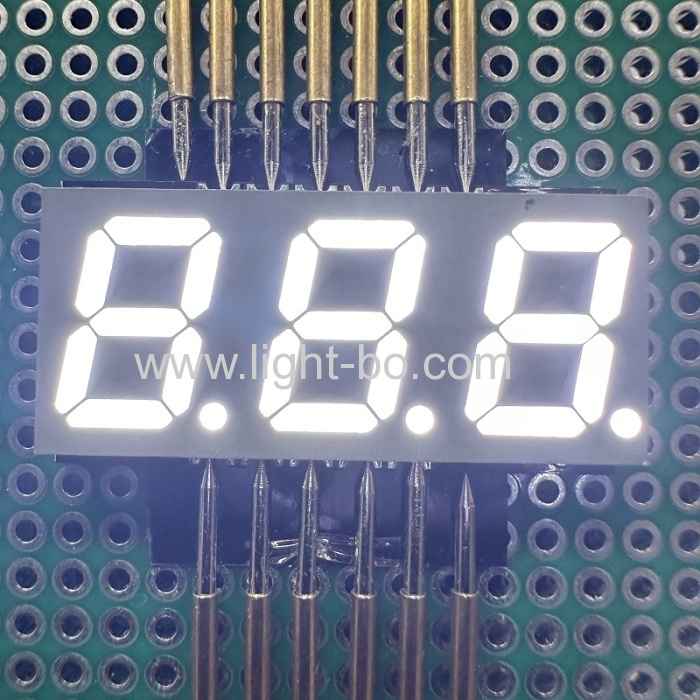

DIP (Pin Through-Hole):

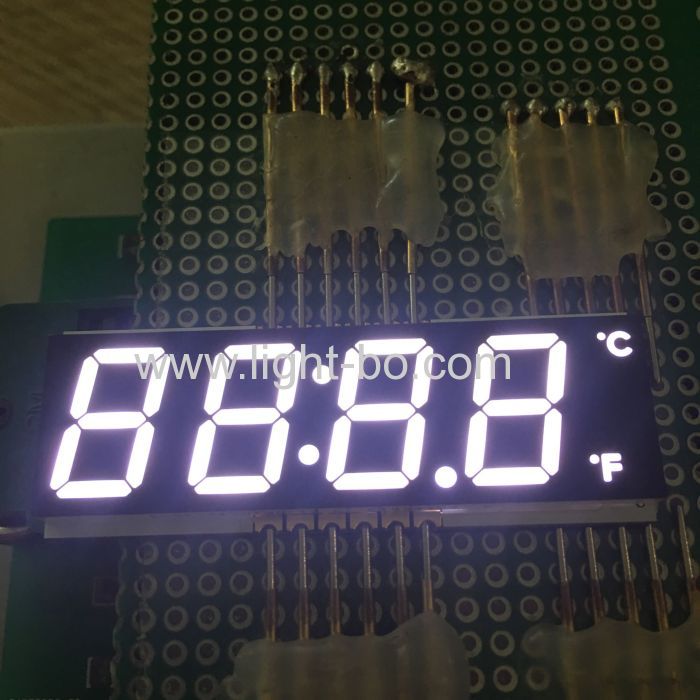

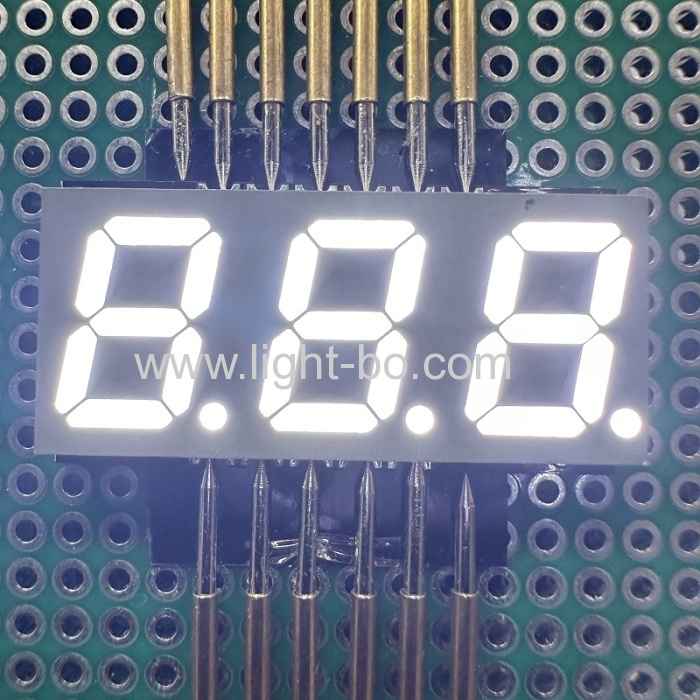

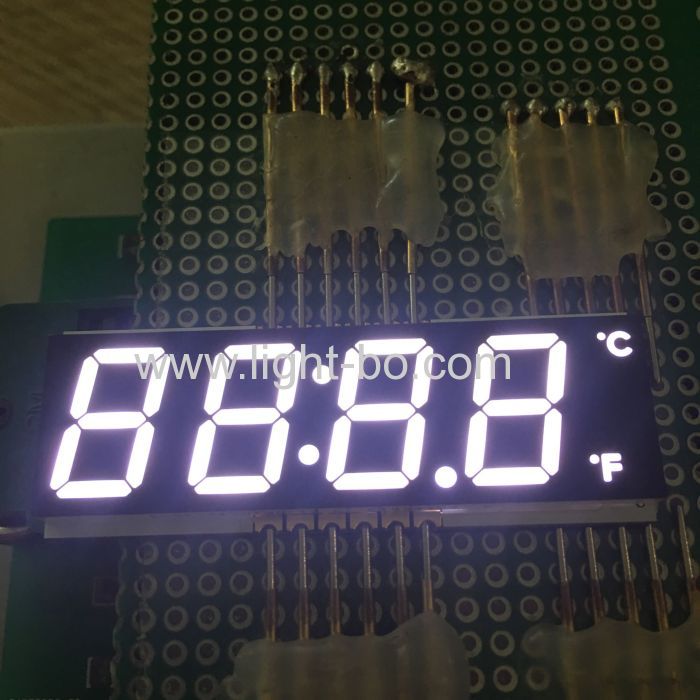

Features long, sturdy pins inserted into drilled PCB holes, secured by soldering on the opposite side .

Pros: Ideal for prototyping (compatible with breadboards), manual assembly, and rework.

Cons: Larger footprint limits miniaturization; not suited for automated production.

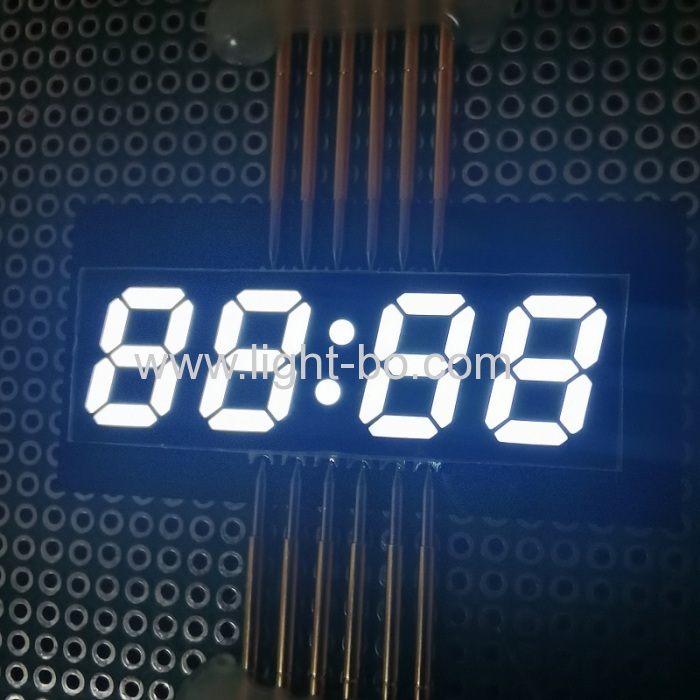

SMD (Surface Mount):

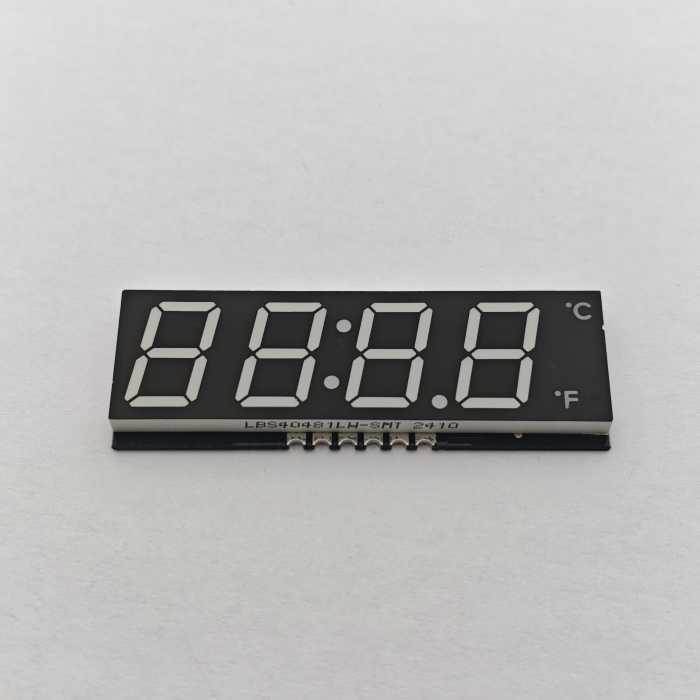

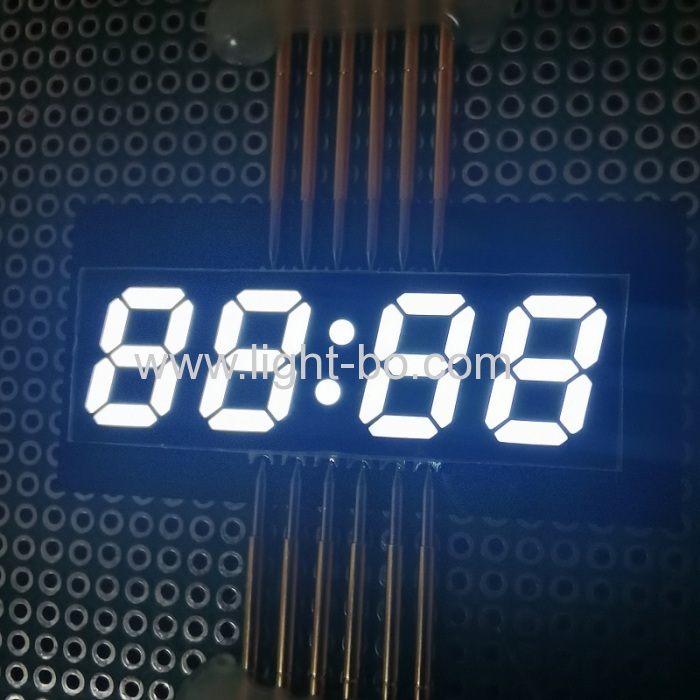

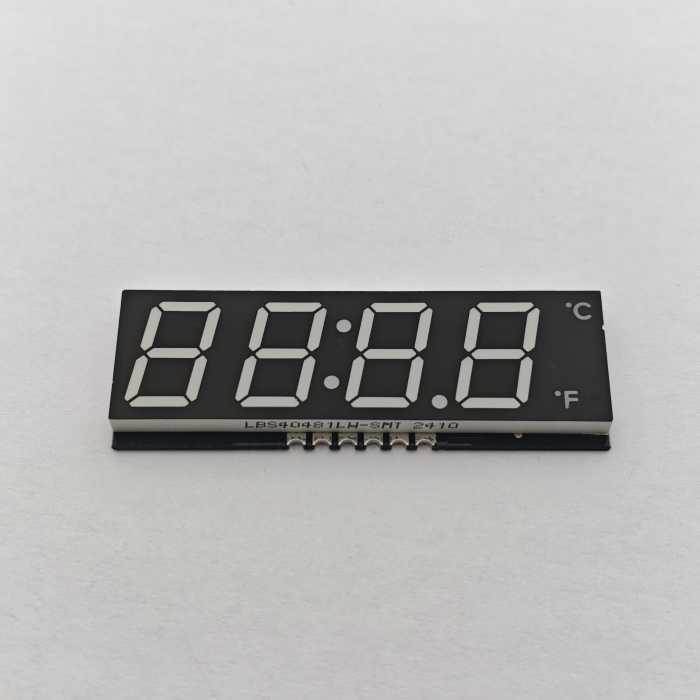

Sits directly on PCB pads, soldered via reflow or wave techniques .

Pros::Compact size saves space , enables lightweight, high-density designs (For example,slim devices like laptops/tablets).

Cons: Requires precision equipment for soldering , harder to repair manually.

2. Electrical & Environmental Performance

DIP

Robust mechanical connection resists vibration/shock .

Higher heat tolerance due to through-hole soldering (suitable for industrial controls).

Wider viewing angles but lower segment density.

SMD

Reduced parasitic inductance/capacitance enhances signal integrity .

Vulnerable to thermal stress in high-power applications,may need heatsinks.

Narrower viewing angles but superior brightness uniformity.

3.

Application-Specific Recommendations

Choose DIP if

Prototyping/testing circuits (easy breadboard integration) .

Projects exposed to mechanical stress ( For example automotive dashboards).

Manual assembly/low-volume production.

Choose SMD if

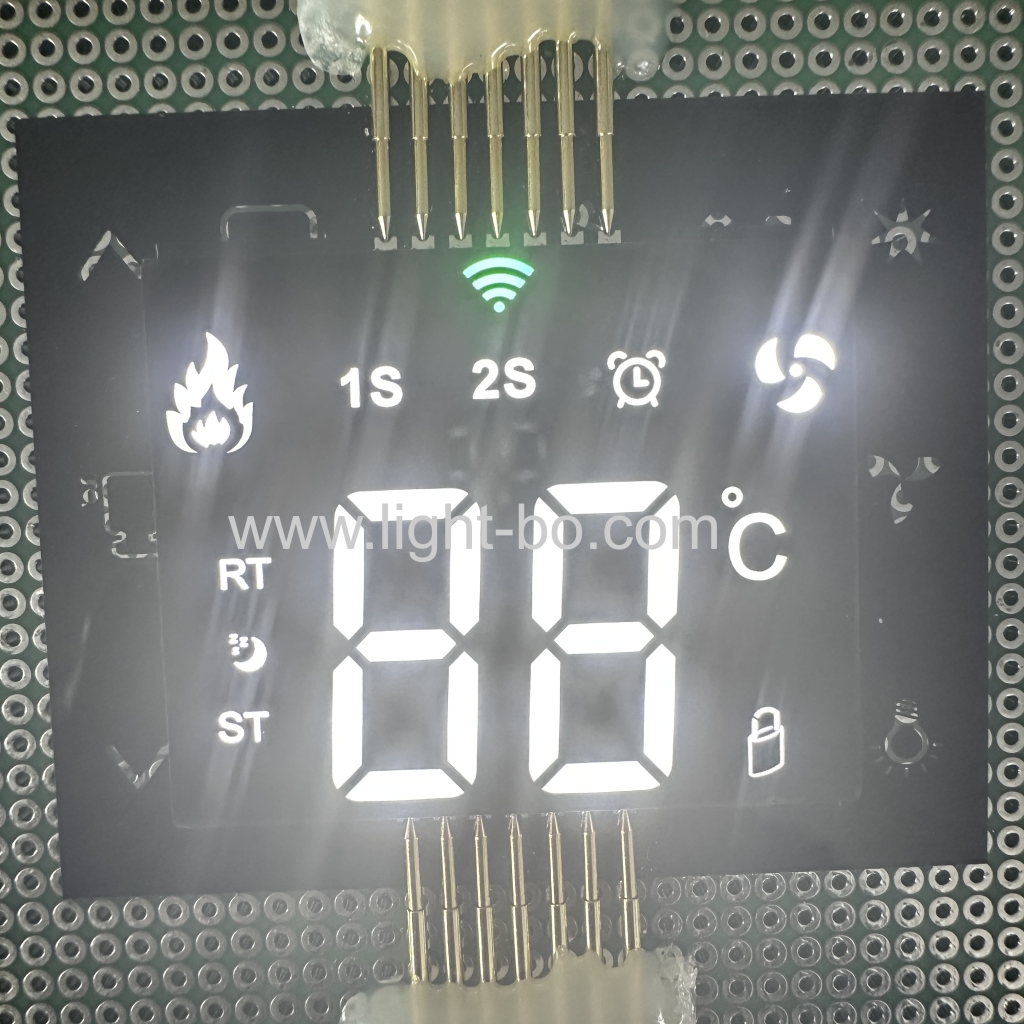

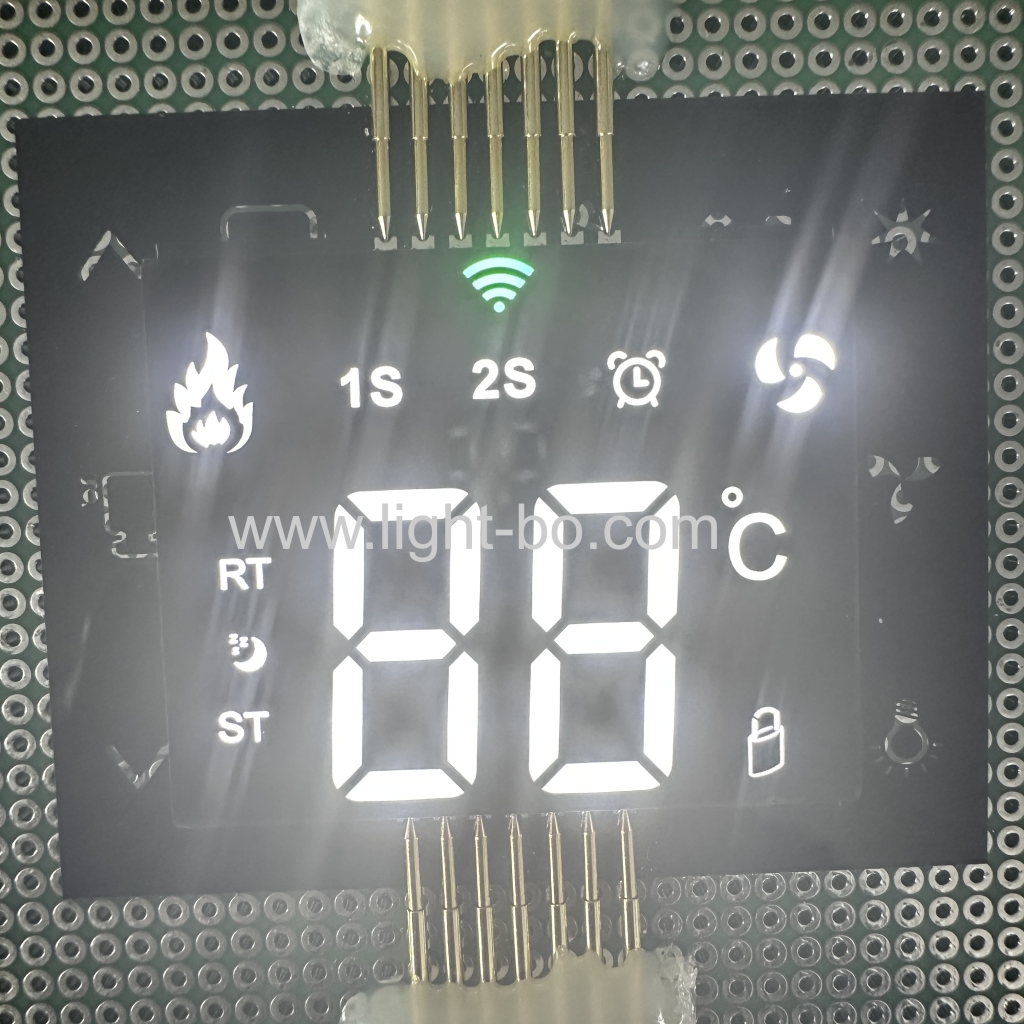

Space-constrained designs (wearables, consumer gadgets) .

High-volume automated manufacturing.

High-resolution displays with tighter segment spacing.

4. Programming & Drive Compatibility

Both types use similar driving logic ( For example GPIO control via BCM/BOARD mode in Python) .

Key difference: SMD variants may integrate multiplexing circuits, reducing GPIO pins needed .

Tip:For SMD, ensure compatibility with drive strength settings (For example, Pin.LOW_POWER vs. HIGH_POWER in MicroPython) .

Decision Flowchart: Quick Reference

Prototype ? ->Manual Assembly ? ->Harsh environment?

-> YES ->DIP

-> NO-Miniaturization? -> Mass production -> YES -> SMD

Conclusion

7 Segment LED Display, 7 Segment Display, DIP 7 segment led, SMD 7 Segment LED, Customized led display,2 digit display, 3 digit display, 4 digit display, led clock display, white led display,green led display,blue led display ,common anode led display, common cathode led display,Alphanumeric LED Display

While DIP displays excel in durability and ease of hands-on development, SMD variants dominate modern electronics with their compactness and automation readiness. Always prioritize

Environmental factors (temperature/vibration),

Manufacturing scale,

PCB real estate constraints .